Development of a microfluidic α-amylase bioreactor - Applicable to bioethanol production 2007 - 08

α-Amylase is a starch hydrolase enzyme which hydrolyzes glycoside bonds in:-

- Polysaccharides

- Oligosaccharides,

Giving rise to:-

- glucose,

- maltose,

- dextrin.

The level of α-amylase in cereal grains and products significantly affects the industrial exploitation.

Breadmaking

- Breaks down complex sugars (starch) into simple sugars (glucose)

- Yeasts then feeds on these simple sugars and converts it into alcohol and CO2.

- This imparts flavour and causes the bread to rise.

- Amylase occurs naturally in yeast, but at very low levels.

- Often a bread improver is used, which contains additional amylase.

- Too much produces sticky crumb, leading to problems in processing

Similarly, In the brewing industry, the level of malt α-amylase is a key quality parameter.

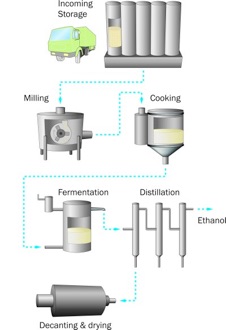

Biofuels

Dwindling supplied of fossil fuels have lead to an increased interest in alternatives, including biofuels such as bioethanol,

This can be added to internal combustion engines in blends of up to 15% without the need for engine modification.

Bioethanol production is considered by some to be a greener alternative to fossil fuels, with bioethanol Prepared by the digestion / fermentation of biological material.

α-amylase enzyme is crucial in this digestion process, and it is thought that Genetic Modification can increase yields of α-amylase in crops, thus inproving the yield of the bioreactor.

However, Expression of α-amylase by corn during the growth cycle is dependant on many factors, including nutrients, water, sunlight availability, and the levels of α-amylase present must be closely monitored, as the Lack of amylase leads to incomplete digestion and thus fowling of the refinery processes.

This in turn is a costly exercise, limiting bio-ethanol production and in worst case scenarios forcing plants to close during cleanup.

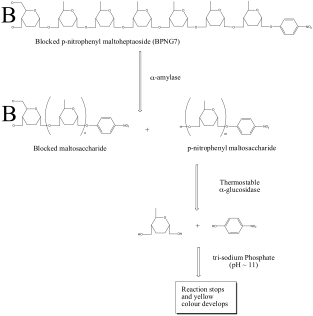

The Megazyme Enzyme Assay

The Amylase HR Assay is a microtitre plate assay for determining enzyme activity.

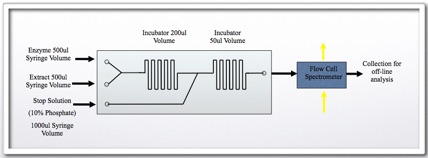

The extract is incubated with a reagent & buffer solution, and The reaction is terminated by the addition of pH11 phosphate buffer. The resulting pH change generates a colorimetric shift, facilitating detection via absorbance at 410nm

This is directly related to the level of α-amylase in the sample.

Instrumentation

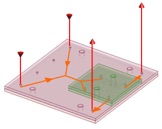

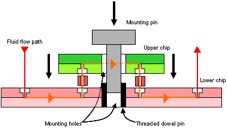

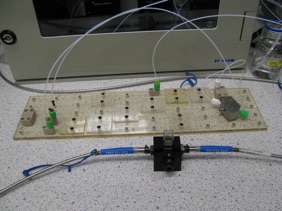

Epigem’s fluence prototyping board was used to construct a prototype microreactor.

Detection was achieved using an ocean optics USB4000 spectrometer and light source, with an external detection cell used in the first instance.

Final designs were proposed to miniaturise the reactor board into a disposable device based on the schematic below.

A custom labview programme was created to control the custom kloehn syringe pump system which consists of 4 V6 48000 step resolution microstep syringe pumps.

Conclusions

The α-amylase assay is of great interest to a number of commercial and research entities.

Current assay procedures require :-

- A microtitre plate incubation system,

- Sample prep laboratory space.

- Skilled Scientists

- Unsuitable for plant-floor operation.

- Takes in excess of 20 minutes for assay completion – low individual assay throughput.

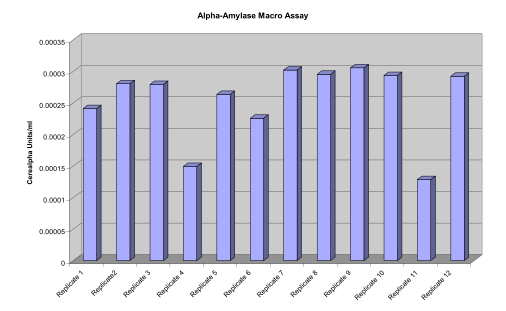

Standard Assay

2.56x10-4 CU/ml

SD 5.94x10-5 CU/ml

The micro-reactor assay system offers :-

- A decrease in assay duration / incubation by a factor of 6.2, from 20 minutes to 3.2 minutes.

- Ability to run as a continuous reaction,

- Shows an increase in reaction efficiency by a factor of 10.

- Suitability for plant-floor operation.

- Relatively unskilled operation

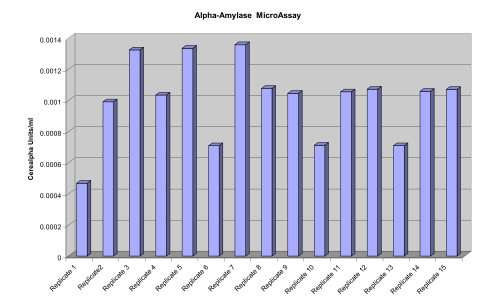

Microfluidic Assay

1.0x10-3 CU/ml

SD 2.5x10-4 CU/ml,